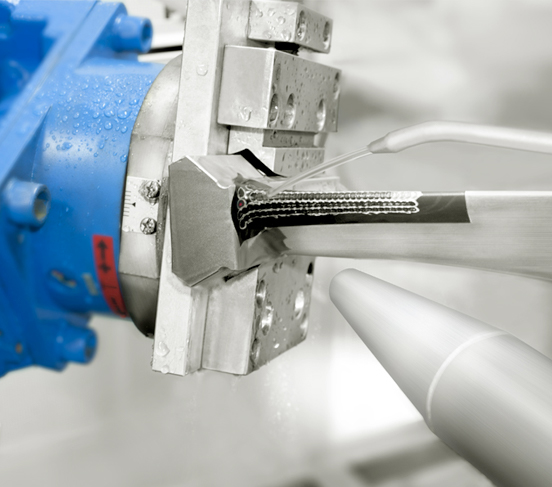

HIGH ENERGY LASER SHOCK PEENING MACHINE

TECHNICAL SPECIFICATIONS:

- Pulse Energy: 5-15J

- Wave Length: 1064nm

- Laser Output Pulse Width: 10-20ns

- Pulse Rate: 1-10Hz

- Positioning Accuracy: ≤0.10mm

- Overall Demission: 7m*3.5m*2.8m (L*W*H)

- Gross Weight: 12 Tons

Humidity Requirement:<60% RH - Laser Warm Up Time: <20 mins

- Operation Temperature: 15℃-25℃

- Applicable to process blisk, blades and critical metal components infactory

LOW ENERGY LASER SHOCK PEENING MACHINE

TECHNICAL SPECIFICATIONS:

- Pulse energy: <200 mJ

- Wave Length: 532nm

- Laser Output Pulse Width: 10ns

- Pulse Rate: >300Hz

- Processing Precision: ±0.020mm

- Overall Demission: 2.4*2.4m*2.4m (L*W*H)

- Gross Weight: 1.8 Tons

- Humidity Requirement:<60% RH

- Laser Warm Up Time: <20 mins

- Operation Temperature: 15℃-25℃

- Applicable to replace shot peening to some degree and achieve more effective result than shot peening